As we look towards the year 2050, the world’s population is projected to reach a staggering 9.8 billion. Alongside social and economic advancements, changing consumer patterns are expected to drive a surge in demand for animal protein-rich diets, possibly increasing by 60-70%. This raises the pressing question: Will our global resources be able to adequately accommodate the dietary needs of such a growing population?

Pioneering Cultivated Meat

The food sector is progressing in its investigation of alternatives to traditional meat production. Cultivated meat is one such promising approach, as it provides environmental benefits while avoiding the need to grow animals only for slaughter.

At the forefront of this innovative field stands Aleph Farms, a leading manufacturer that is taking significant steps towards commercializing cultivated meat by the year 2024. Based in Israel, the company is now expanding its operations into Singapore, currently the only country where consumers can savor lab-grown meat.

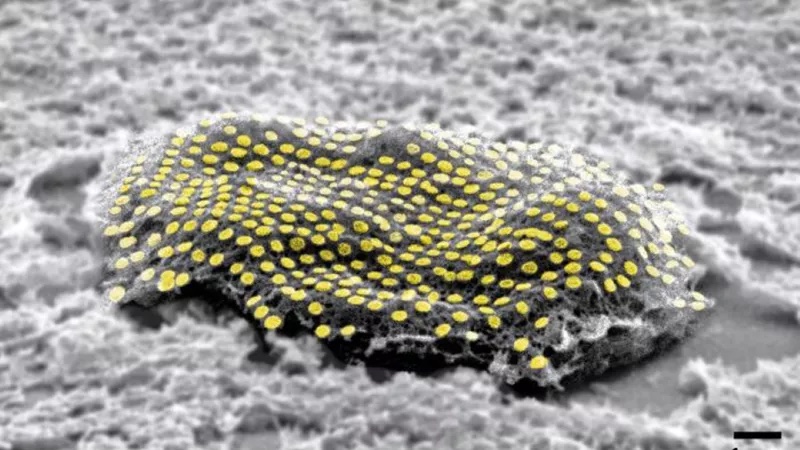

Cultivated meat boasts striking similarities to conventionally sourced meats like chicken, fish, pork, and beef, making it essentially indistinguishable from the real thing. The key difference lies in the production method, where animal cells are cultivated in laboratory settings. Muscle stem cells extracted from real animals are transformed into meat within carefully controlled environments.

The production process starts with getting stem cells from an animal and putting them in a bank. Then, these cells are grown at high densities and amounts in bioreactors, which are also called cultivators in everyday language. The cells are given an oxygen-rich cell culture medium made of basic nutrients like amino acids, glucose, vitamins, and inorganic salts. Growth factors and other proteins are also added to the medium.

Changes in the makeup of the medium, often in combination with signals from a scaffolding structure, tell immature cells to become skeletal muscle, fat, and connective tissues, which are what make up meat. The differentiated cells are then taken out of the culture, cleaned, and put into end products. Depending on what kind of meat is being grown, this process should take between 2 and 8 weeks.

Recognizing the potential of cultivated meat, Aleph Farms is proactively enhancing its production capabilities in preparation for the commercialization of its lab-grown specialty. The company recently acquired a manufacturing facility in Modi’in, Israel, along with related equipment from VBL Therapeutics, a renowned biotechnology company. This strategic move will enable Aleph Farms to produce cultured meat locally in Israel by 2024.

A Global Footprint

Looking beyond its home base, Aleph Farms has signed a Memorandum of Understanding (MOU) with ESCO Aster, the sole company with full regulatory approval for commercial sales of cultivated meat. Together, they aim to introduce cultivated meat to the Singaporean market by 2025, providing a much-awaited option for consumers in the region.

With a focus on introducing its thin-cut steak grown from cells, Aleph Farms envisions launching the product initially in Israel and Singapore. Their strategy involves building production capacity rapidly and efficiently in these locations, while simultaneously planning for additional strategic assets worldwide. This approach aims to bolster food system security and resilience on a global scale.

The Kosher stamp

In a significant development, Aleph Farms’ cultivated steak has been recognized as kosher by the Chief Rabbi of Israel, David Baruch Lau. This ruling ensures that the meat is permissible for consumption under religious law by Jews, combining innovation with adherence to culinary traditions.

The prospect of feeding an ever-growing global population poses challenges, but cultivated meat represents a sustainable and ethical alternative to traditional animal farming. With companies like Aleph Farms leading the way, the world is moving closer to a future where dietary needs can be met without compromising environmental and ethical concerns.